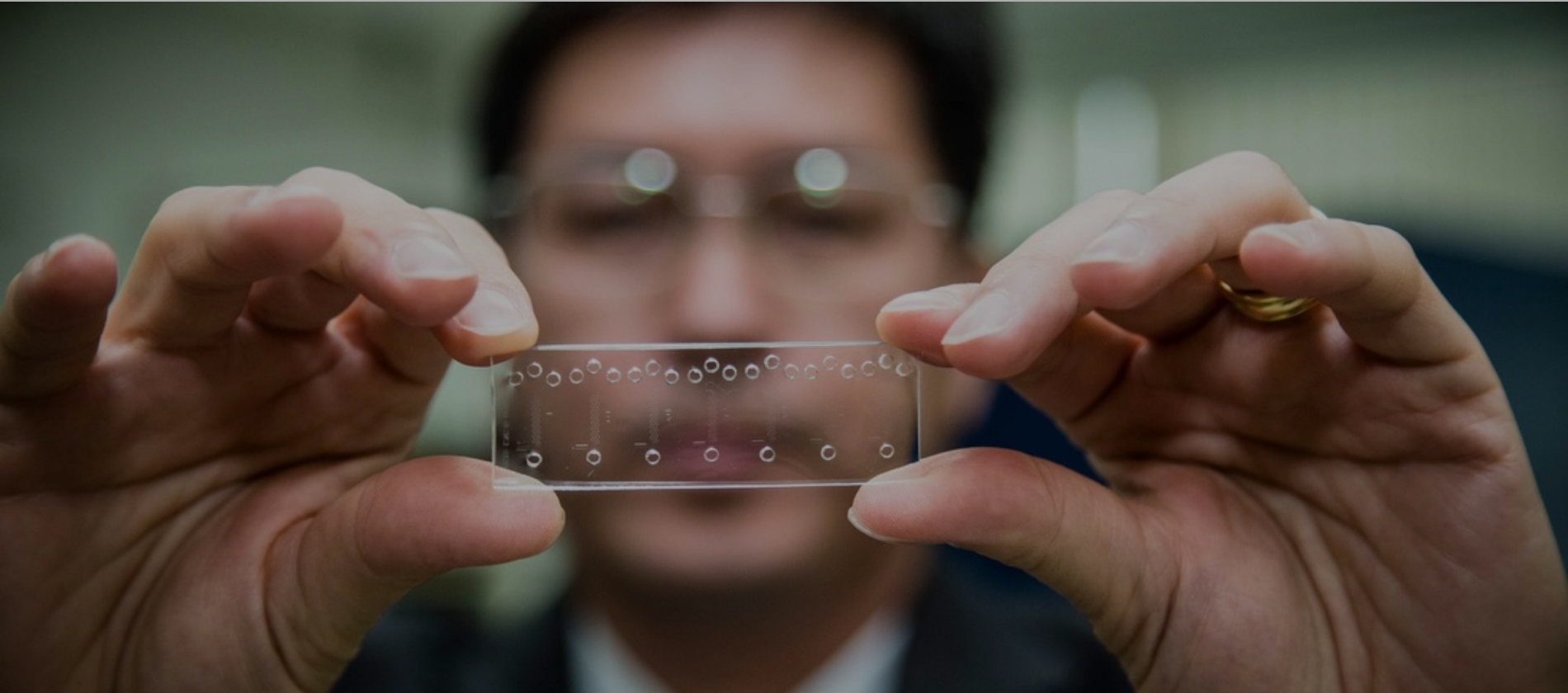

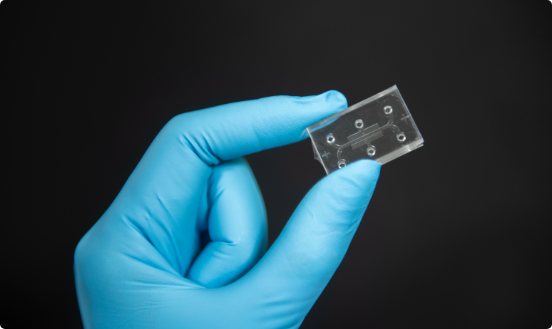

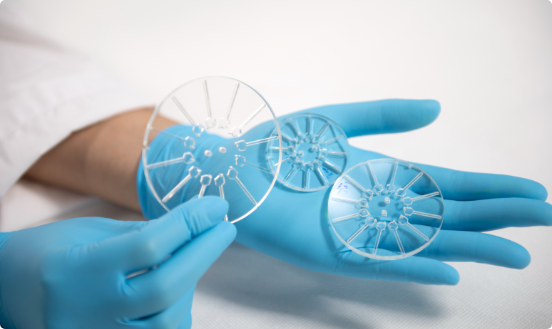

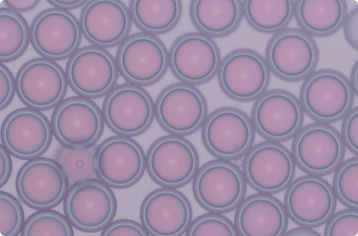

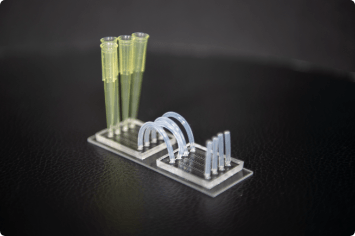

There are a handful of technologies currently used to manufacture microfluidic chips such as Casting, stamping, rolling or laminating, micro-machining, injection molding, etching, and additive manufacturing. Feature size is the most important factor in the fabrication of Microfluidic devices. Based on our Si-based CMOS compatible facilities, the small feature size of the micro-channels can be miniaturized to 0.5 micron.

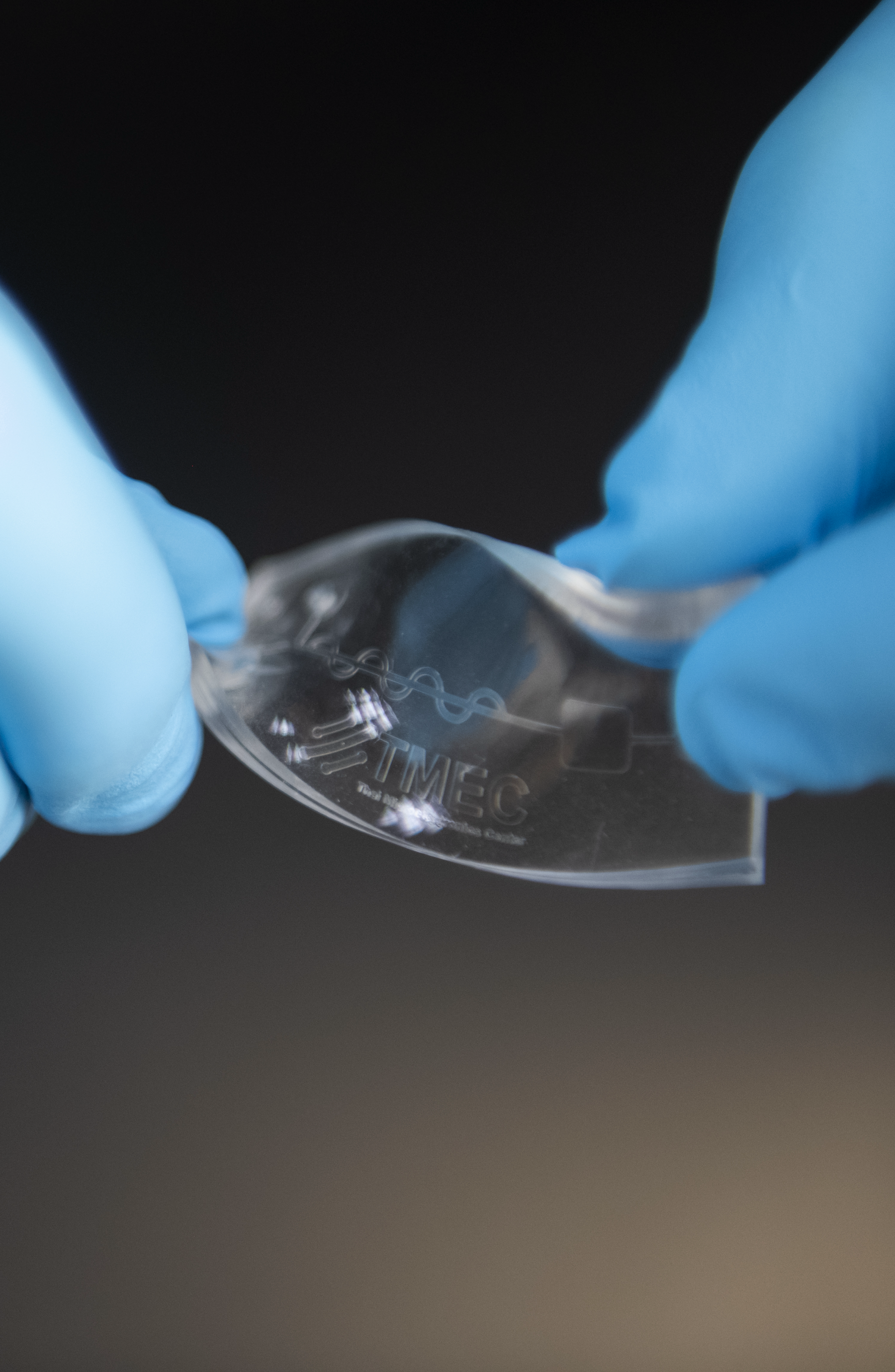

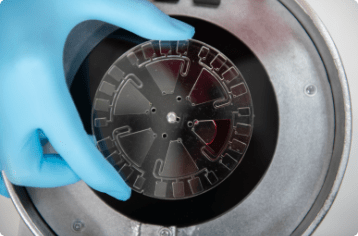

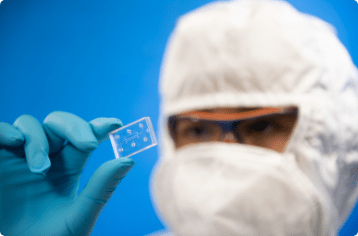

TMEC offers flexible process based on soft lithography and laser machining processes for the microfluidic chip manufacturing, handling and packaging, which are performed in our industrial cleanroom facility. The silicon master molds, plastic master molds, photoresist soft molds, and the intermediate polymer molds are fabricated in-house for good pattern qualities control and client’s IP protection with shorter lead time, faster turnaround and reasonable prices.